The Federal Aviation Administration (FAA) has issued two airworthiness directives (AD) for operators of the Airbus A380. Operators with Engine Alliance (EA) GP7200 installed are being instructed to conduct independent inspections for cracking and wear.

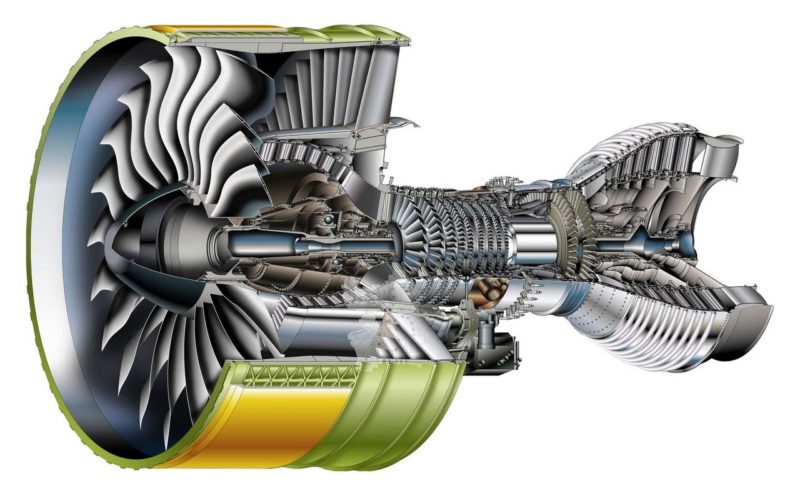

For all EA GP7270, GP7272, and GP7277 engines the AD requires an initial inspection of the high-pressure compressor-HPC stage 6 seal ring for correct installation, also an inspection of the HPC stages 2-5 spool for cracks or missing coating.

The second AD is only for certain GP7270 and GP7277 models and requires a one-time ECI of the engine fan hub blade slot bottom, a blade slot front edge for cracks, and a visual inspection of the engine fan hub assembly for damage.

For those airlines who have the serial number that requires the fan hub assembly replacing entirely, the cost per product will be significant. The FAA estimate 50 work-hours plus a part cost of $790,500, bringing the total expense to $794,750 per engine.

These inspections are an evolution of the regime implemented after an Air France A380 suffered an un-contained GP7200 engine failure over Greenland in September 2017.

Back then, Flight 66 was on route from Charles de Gaulle to Los Angeles International when the entire fan module including blades and disc, separated from the engine. An extensive search to find crucial engine components was launched, which had been buried by heavy seasonal snowfall – a search which proved successful earlier this year.

MRO Network estimates that the Engine Alliance GP7200 engines power 60% of the world’s A380s, including: Emirates, Etihad, Air France, Korean Air, and Qatar. All of these operators will need to perform the inspections, although not all the engines will require replacement.

Both Airworthiness Directives come into effect on the 30th August 2019. The FAA has given airlines until 1st September 2020 to comply.