On 8th July 2024, a United Airlines Boeing 757 bound for Denver lost one of its main landing gear tires while taking off from Los Angeles. This is the second time in four months that a tire has fallen from a United aircraft during take-off.

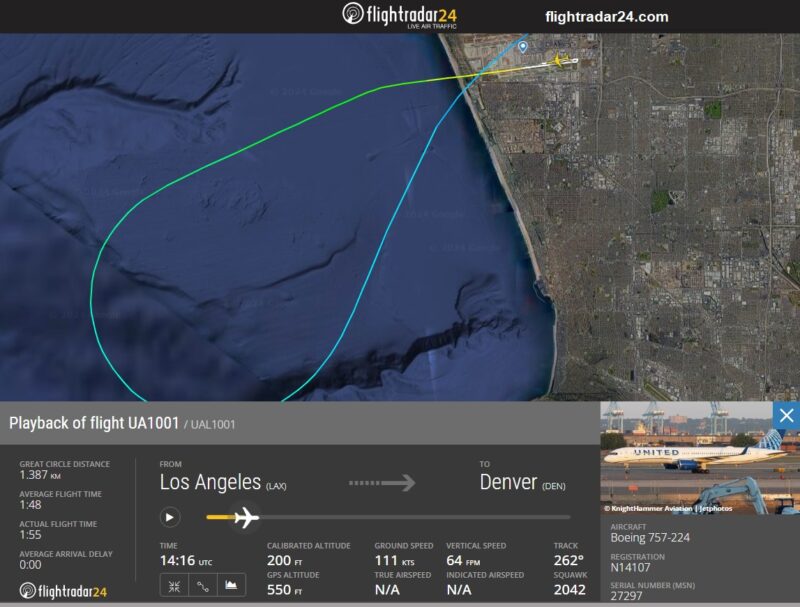

The Boeing 757-200 with registration N14107 was performing flight UA1001 from Los Angeles (LAX) to Denver (DEN) with 174 passengers and 7 crew. However, while the B757 was climbing out of LAX’s runway 25R, a main wheel detached and fell onto the car of an airport employee, as reported by the Aviation Herald.

Pilots of other aircraft on taxiways observed the tire detaching from the B757 as it became airborne. Despite the tire loss, the decision was made to continue the flight to Denver, as it was deemed safer and more convenient for passengers.

Footage shared on social media shows the tire plunging on the runway. The tire was recovered in the vicinity of LAX. “The wheel has been recovered in Los Angeles, and we are investigating what caused this event,” said an airline spokesperson.

Upon approaching Denver, the pilots declared an emergency, instructing passengers to brace for landing. The aircraft landed on runway 34L and vacated the runway on its own before being towed to the apron.

Previous Incident

This incident mirrors a similar incident in March 2024 when a United Airlines Boeing 777 lost a main landing tire during takeoff from San Francisco International Airport. That tire also caused damage in an employee parking lot. Following the incident, the B777 bound for Japan diverted to Los Angeles for a thorough inspection.

Both United Airlines and the FAA have initiated investigations into the cause of the tire loss. The FAA is collecting information, and the NTSB may also get involved, though no statement has been issued yet.

United Airlines assured passengers that safety remains a top priority and expressed gratitude for the professionalism of the pilots and crew. The airline is also coordinating with LAX authorities regarding the incident and any necessary follow-up actions.

FAA Mandates Inspections on Boeing 737

The Federal Aviation Administration (FAA) has ordered immediate inspections of oxygen masks on approximately 2,600 Boeing 737 aircraft due to issues with adhesive materials causing the masks to shift out of position. This fault could prevent the provision of supplemental oxygen to passengers during a depressurization event.

The directive affects both older and newer models of the Boeing 737. Airlines must perform visual inspections and, if necessary, replace oxygen generators, strap thermal pads, and reposition any impacted units within 120 to 150 days, based on the specific 737 model.

The problem stems from a new adhesive introduced in August 2019 on the restraining straps of the oxygen generators. Boeing has reverted to the original adhesive for new deliveries to ensure stability. Although no in-service units have failed to operate properly, the FAA’s directive aims to prevent potential issues by barring the installation of defective parts.

Quality Control Under Scrutiny

This inspection order adds to the mounting pressure on Boeing to improve its quality control measures. Earlier this year, a Boeing 737 MAX 9 operated by Alaska Airlines experienced an in-flight separation of the rear mid-cabin exit door. Such events underscore the critical importance of stringent quality control practices in ensuring passenger safety.

Each Boeing 737 typically has 61 oxygen generators, each secured by two straps. The directive aims to ensure that all oxygen mask units are securely positioned to provide necessary supplemental oxygen in an emergency.

Featured Image via Airline Videos