Today a United Airlines Boeing 777-200 experienced a serious failure of engine #2, shortly after take-off from Denver International Airport; the aircraft has scattered parts from the engine over the Broomfield neighborhood.

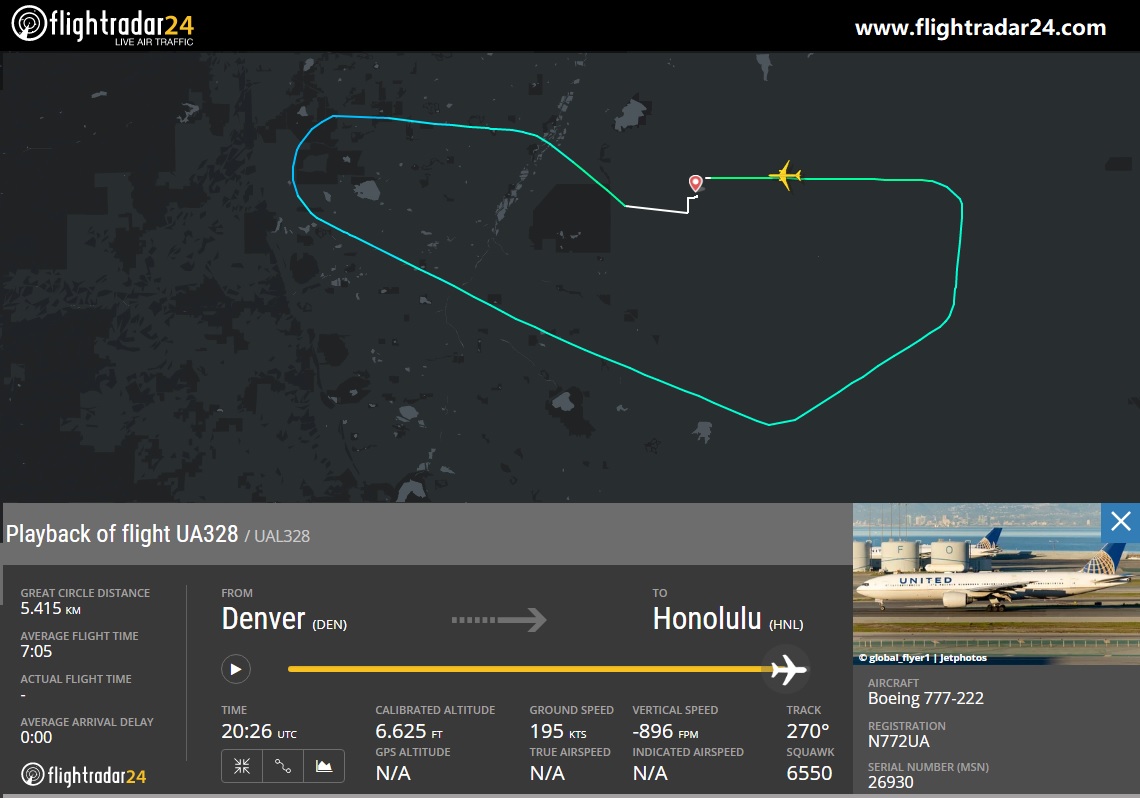

According to the AvHerald, the 26-year-old aircraft, registration N772UA and performing flight UA-328 from Denver to Honolulu (USA), was in the initial climb out of Denver’s runway 27 when the right-hand engine’s (PW4077) inlet separated; this separation is associated with the failure of the engine.

The crew declared Mayday after reporting the engine failure, they stopped the climb at about 13000 feet and requested the return to Denver; they then proceeded to make a safe landing on runway 26, about 23 minutes after departure. On-board were 231 pax and 10 crew, no injuries have been reported.

“UA328 experienced an engine failure shortly after departure, returned safely to Denver and was met by emergency crews as a precaution.”

said United Airlines

The FAA statment:

Almost Identical to the 2018 Uncontained Failure a United 777 Experienced

Back in February 2018, another United Airlines Boeing 777 experienced an almost identical uncontained engine failure. Fitted with Pratt and Whitney PW4000 engines, N7773UA was at the top of its descent into Honolulu when the number two (right) engine released a fan blade.

Video captured by passengers as well as on-ground inspection revealed most of the inlet duct and the side fan cowls were missing. Two punctures were also found on the right side fuselage below passenger windows, with impact models confirming fan blade debris was responsible.

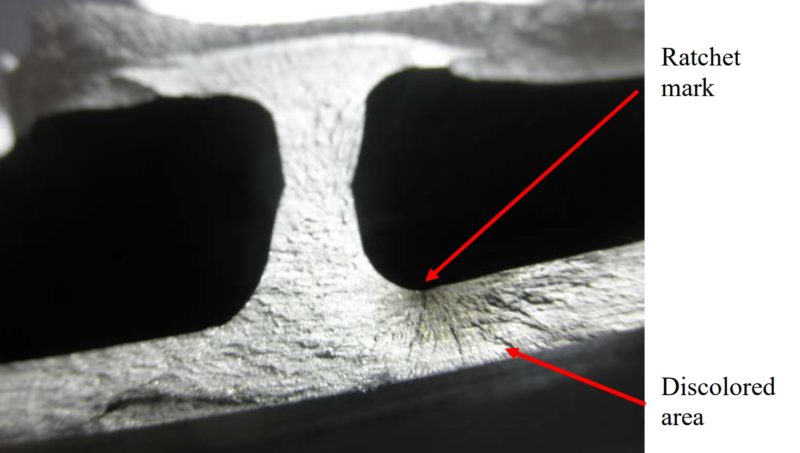

The National Transportation Safety Board (NTSB) confirmed in their investigation that blade number 11 was primarily responsible for the engine failure, fracturing in a transverse manner.

As per the NTSB report, metallurgical examination revealed a fatigue fracture that had initiated from a subsurface origin in a region of micro texturing consisting mostly of primary alpha crystals on the interior surface of the hollow core fan blade.

Photo: NTSB

Photo: NTSB

At the time of the incident the engine had accumulated 77,593 hours since new, 13,921 cycles since new and 8,579 hours and 1,464 cycles since the last overhaul.

To better help the overhaul and maintenance process, Pratt and Whitney relied on fluorescent penetrant inspection as well as their thermal acoustic imaging process developed in 2005 for the PW4000 series.

Combining the engines history, its maintenance procedures and training anomalies identified during the investigation, the NTSB determined the probable cause of failure as the following:

“…the fracture of a fan blade due to P&W’s continued classification of the TAI inspection process as a new and emerging technology that permitted them to continue accomplishing the inspection without having to develop a formal, defined initial and recurrent training program or an inspector certification program. The lack of training resulted in the inspector making an incorrect evaluation of an indication that resulted in a blade with a crack being returned to service where it eventually fractured. Contributing to the fracture of the fan blade was the lack of feedback from the process engineers on the fan blades the inspectors sent to the process engineers for evaluation of indications that they had found.”

National Transportation Safety Board

The Investigation Process

Despite the stark similarities between the two incidents, no verdict can be made until an investigation is complete.

Factors such as production records, maintenance records, operational history, weather conditions, external interference and crew response are among the countless amounts of information the NTSB will process to determine the root cause of the incident.

Upon final verdict, the report will be available to the public, with the potential for an airworthiness directive delivered to airlines to prevent such incident occurring again.