General Electric has recalled all delivered GE9X engines that power the Boeing 777X, for an immediate redesign.

The recent announcement, that the engine test and certification program would be delayed, has further impacted Boeing by setting back 777X progress.

Citing Flight Global, the news comes as Volga-Dnepr filed an application to the U.S. Department of Transportation for rights to transport engines between Washington and Ohio.

General Electric states four engines will be transported from Washington to Ohio, to undergo inspection, and have redesigned components installed.

The four engines being sent back are of the “compliance category” meaning they will be the ones powering the multiple 777-9 test aircraft.

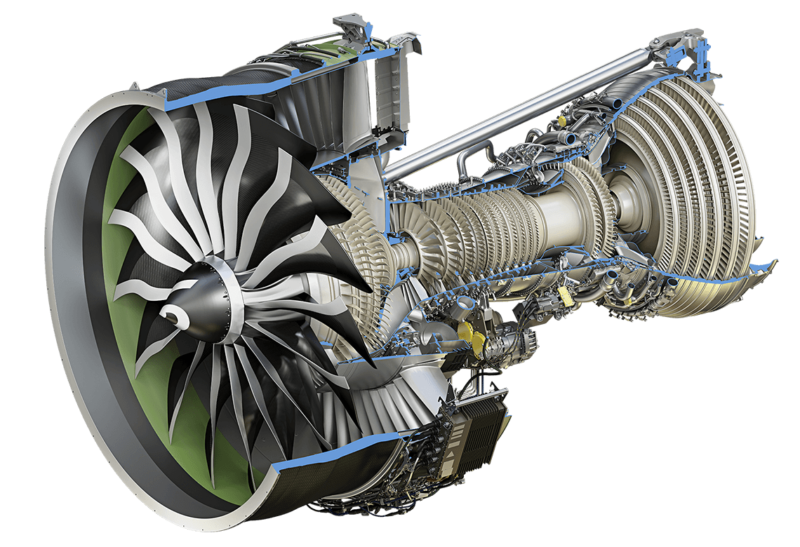

Continuous testing of the engine has identified a design flaw, this flaw requires stator vanes in the second stage of the high-pressure compressor to be redesigned.

Analysis of the problematic component produced information regarding increased wear and exhaust gas temperatures, significantly higher than optimal limits.

General Electric maintains the redesigned component won’t hinder efficiency and performance promises.

Despite the setback, Boeing aims to fly, test and deliver the 777X in 2020 – an ambitious and aggressive test campaign.

Volga-Dnepr will utilise an Antonov AN-124-100 Freighter to transport the engines between facilities, along with their associated equipment.

Due to the enormous size of the GE9X engines, an exemption had to be made as no U.S. based airline has the ability to haul such a significant piece of equipment.

The document states the following size and weight of the engines as the following:

- 8 x 4 x 4m (26 x 14 x 13ft)

- 36,000lb (16,300kg)

Emphasizing the importance of the exemption, Volga-Dnepr outlines a failure to deliver the engines by air could result in greater delays to the 777X program; this would result in significant financial harm to Boeing, GE and customers.

The news isn’t entirely doom and gloom for the GE9X, however.

Testing has unveiled the engine has the ability to produce over 134,000lbs of thrust – a world record!

The only remaining tests are emissions and block testing, which include running the engine 25 times for a period of six hours with the exhaust gas temperature (EGT), fan speed and core speed at maximum “redline” indications.

With the redesign in progress, it’s unknown when these tests will be completed and how far the engine is from complete certification.

For those desperate to hear the new flagship in action, check out this video: