The Federal Aviation Administration (FAA) has issued a new airworthiness directive (AD) for the Engine Alliance (EA) GP7200 that powers the Airbus A380.

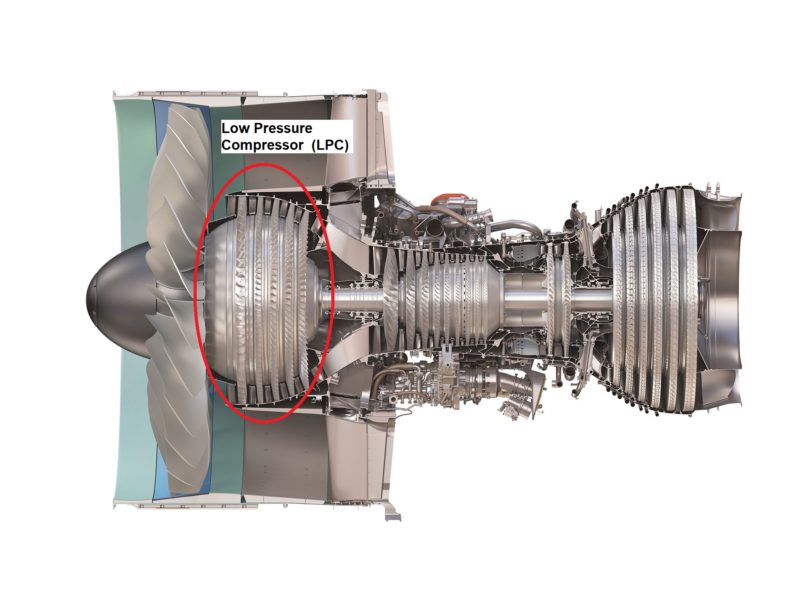

This AD requires an ultrasonic inspection of the low-pressure compressor (LPC) 1st-stage fan blades and, depending on the results of the inspections, a possible replacement of any affected fan blades.

What is the Problem With This Engine?

According to the FAA, this inspection is an evolution of the regime implemented after a recent in-flight shutdown (IFSD) that occurred during a revenue flight on March 10th 2019.

The FAA didn’t specify the airline but on the day in question an Air France A380, performing flight AF703, had to return to Abidjan after reporting an engine failure.

“The IFSD resulted from the fracture of two LPC 1st-stage fan blades. The cracks originated in a microtexture area that can result in a low-cycle fatigue debit, that may allow a crack to initiate and propagate to failure.”

“After an analysis of these fractures, the manufacturer determined the fan blades experienced cracks that originated on the internal surface of the convex airfoil and propagated to the point of failure.”

states the FAA

This condition, if not addressed, could result in an uncontained fan blade release, causing damages to the engine and consequential damage to the airplane.

The airworthiness directive was published on December 30th 2019 and is effective on January 14th 2020.

Costs

The A380 can be powered by two types of engine: Engine Alliance GP7200 or Rolls Royce Trent 900.

From the 15 operators of the A380, only 5 will be affected by this AD. They are Air France, Emirates, Etihad Airways, Korean Air and Qatar Airways.

For the airlines named before, the cost per product may be significant if the fan blade needs to be replaced.

To perform an ultrasonic inspection for one set of blades, the FAA estimates that it will take around eight hours to inspect each engine. With a cost of $85 per hour each engine will cost $680, but seeing that the A380 has 4 engines the total cost will be $2720.

However, if the company needs to replace a fan blade it will be much more expensive. The FAA estimates 4 work-hours ($85 per hour) plus a part cost of $190,000, making a total of $190,340.

Previous Problems

In September 2017, an Air France A380 suffered an uncontained GP7200 engine failure over Greenland.

Back then, Flight 66 was on route from Charles de Gaulle to Los Angeles International when the entire fan module, including blades and disc, separated from the engine. An extensive search to find crucial engine components, which had been buried by heavy seasonal snowfall, was launched – a search which proved successful last year.

For those interested in additional details, here is the article:

Covered Image by A380spotter

Impressive.

And they can’t find the Malaysian airlines plane.