The Federal Aviation Administration (FAA) issued a new airworthiness directive (AD) to operators of the Airbus A220. According to the FAA, the reason for four in-flight shutdowns was an acoustic resonance.

This AD concerns Pratt & Whitney PW1519G, PW1521G, PW1521G-3, PW1521GA, PW1524G, PW1524G-3, PW1525G and PW1525G-3 model turbofan engines.

What is The Problem With This Engine?

Last year there were 3 in-flight shutdowns involving Swiss A220 aircraft, powered by the P&W1500G engine. Another incident occurred last month with an Air Baltic aircraft.

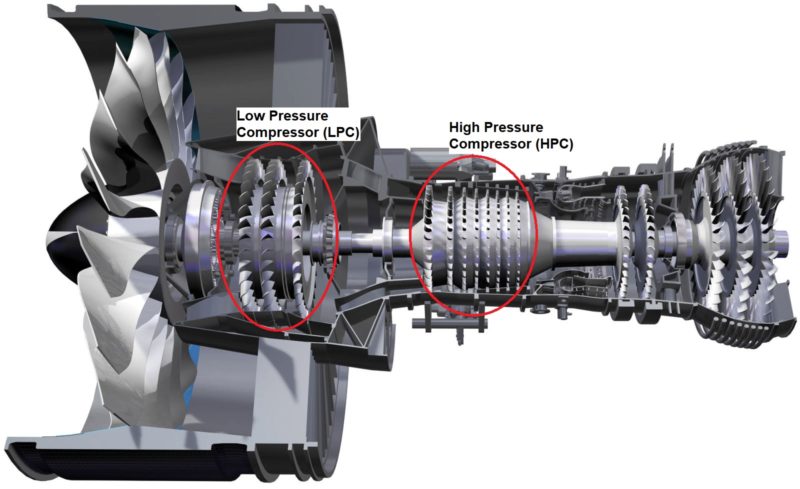

Right after the first incidents, the FAA order inspections and they found that the reason for the incidents was the failure of the LPC Stage-One Rotor.

Analysis by the manufacturer determined that the Low-Pressure Compressor (LPC) vane schedules were putting the engine in a condition to experience an acoustic resonance, that damages the LPC Stage-One Rotor subsequently leading to its failure.

This AD requires the removal of the Electronic Engine Control (EEC) software if the version is earlier than the Full Authority Digital Electronic Control (FADEC) software version V2.11.9.2. The revision of the FADEC software intends to avoid the resonance phenomenon.

“The FAA considers these LPC R1 failures to be an urgent safety issue, requiring immediate action involving replacement of the EEC FADEC software.”

If the engine has flown less than 300 flights, this will need to be done within 15 flight cycles; these engines are the highest risk for LPC R1 failures. For all other engines, the software upgrade must take place within 90 days.

The FAA states that the engine failures occurred on engines that had been shipped to operators as spares, not delivered installed on the aircraft. All four failures occurred within 300 flight cycles of their subsequent installation.

This unsafe condition, if not addressed, could result in the uncontained release of the LPC R1, in-flight shutdown, causing damage to the engine and consequential damage to the airplane.

What is the problem with this engine ? Is this a serious question ? This engine isn’t the Beautiful engines (Real “whisper-jets”) on the Legendary MD-95. This engine isn’t a GE engine either. Your question is like asking, what is the problem with the engines on a Sukhoi Superjet ?