Boeing's ecoDemonstrator program has been designed to accelerate innovation, by taking promising technologies out of the lab and testing them in the air; to improve sustainability for airlines, passengers and the environment.

The 2020 program was conducted in partnership with Etihad Airways, on one of their new Boeing 787-10 Dreamliner airplanes, expanding a strategic sustainability alliance that the two companies formed in the fall of 2019. Other key partners included NASA and Safran Landing Systems.

Flight testing on the four projects was conducted over eight days at Boeing’s facility in Glasgow, Montana and featured two transcontinental flights between Seattle, Washington and North Charleston, South Carolina.

![Invalid request error occurred.]() Aeroacoustic Research

Aeroacoustic Research

The most comprehensive NASA aircraft system noise flight tests ever were conducted in collaboration with the agency. More than 1,000 microphones on the ground and 214 acoustic sensors attached to the outside of the 787, including over 50 unique test configurations, recorded sound levels.

The testing generated 1.6 terabytes of noise data and the tests objectives were fully accomplished. These objectives will improve NASA’s airplane noise prediction capabilities, advance ways for pilots to reduce noise and provide data for future quiet aircraft designs.

![Invalid request error occurred.]() Quieter Landing Gear

Quieter Landing Gear

Up to 30% of noise from an airplane approaching an airport is caused by air flowing around the landing gear. Testing was performed using landing gear built by Safran Landing Systems and designed to be quieter. Modifications included perforated fairings, which covered part of the nose landing gear, and airfoil-shaped fairings, wrapped around struts on the main gear. Eight acoustic sensors, mounted on the landing gear, augmented the 1,200 microphones used by the NASA project to record sound. Data from the testing is still to be completely analysed, however preliminary results have been positive; observers on the ground heard a noticeable reduction in noise.

![Invalid request error occurred.]() Efficient Flying

Efficient Flying

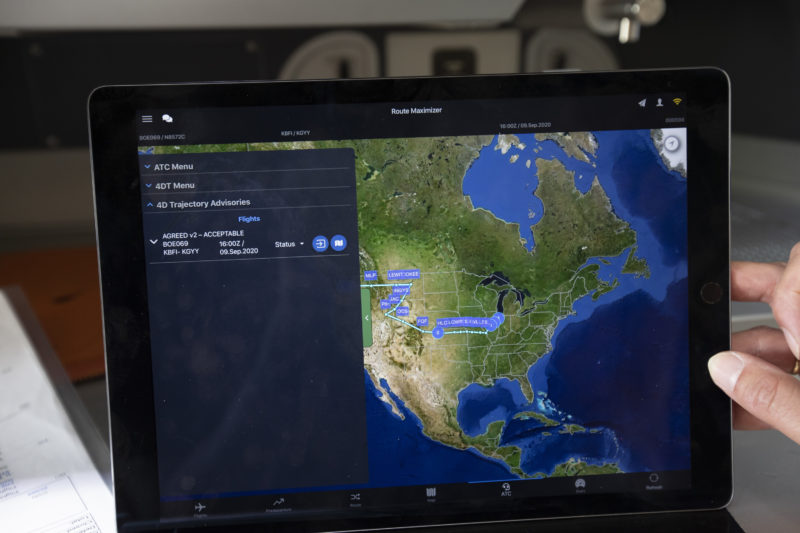

A new system was tested that connects pilots, air traffic controllers and airline operation centres simultaneously, to optimize airplane flight routing and arrival time. Tools included a text messaging system, flight path application and NASA’s Tailored Arrival Manager.

The system simplifies the process for course changes, due to weather and traffic, and minimizes holding time before landing. This enhances safety by reducing radio frequency congestion and pilot-controller workload, while also saving time and fuel and consequently lowering CO2 emissions. The testing included 17 re-routings, during two transcontinental flights across the United States.

![Invalid request error occurred.]() Onboard Disinfection

Onboard Disinfection

A handheld ultraviolet light wand was tested for its effectiveness in disinfecting an airplane. Using a 222 nanometre wavelength UV light, the wand disinfected the 787 flight deck in less than 15 minutes.

An antimicrobial surface coating was also tested on the flight deck during the 16 flights.

These projects are part of a combined effort by Boeing, Etihad and the industry to identify the safest, and most effective, methods of disinfecting the interior of an airplane; in an attempt to make travel safer and more sustainable, with passenger wellness at the core.

![Invalid request error occurred.]() Sustainable Fuel

Sustainable Fuel

All the ecoDemonstrator test flights used a blend of sustainable and traditional aviation fuel to lower CO2 emissions. Several flights flew on 50,000 US gallons of a 50/50 blend; demonstrating the viability of sustainable aviation fuel, at the maximum approved blend for commercial airlines.

The fuel was produced from inedible agricultural waste at the World Energy refinery near Los Angeles. The Roundtable on Sustainable Biomaterials certified that the fuel reduces carbon emissions by more than 75% over the fuel’s life cycle.

Article Source and Image: Boeing