Aviation will play a key role in transporting ground breaking vaccines in the fight against COVID-19. From the moment the wheels touch down it is a race against the clock, and the heat, to get the vital supplies to their final destination safely.

IATA estimates that the equivalent of 8,000 Boeing 747 freighters will be required for the airlift, which will take up to two years to supply some 5-10 billion doses of vaccine.

“This will be the largest and most complex logistical exercise ever....The world is counting on us.”

Alexandre de Juniac, CEO of IATA

I recently interviewed Henrik Ambak, VP of Cargo Operations Worldwide, and Julian Sutch, Pharma Global Sales at Emirates SkyCargo, on their readiness of the next challenge in aviation - transporting the COVID vaccine.

Walk me through the entire process of logistics in place for transporting vaccine.

Air cargo carriers such as Emirates SkyCargo transports vaccines and other shipments from airport to airport. Pharma manufacturers work with forwarders for end to end transportation, from the manufacturing facility to the consignee. Forwarders work with air carriers, shipping lines, road transportation companies and so on to manage the complete logistics.

What are the requirements of transporting vaccines?

Every day we carry pharma and vaccines around our global network, across six continents. In 2019, for example, Emirates SkyCargo transported more than 75 million kilograms of pharmaceuticals on its aircraft.

Emirates’ pharma facilities in Dubai have dedicated temperature controlled zones to store and handle the vaccines, this also includes dedicated cool cells to store the cargo in 2-8˚C or 15-25˚C temperature ranges. Overall, the two facilities offer a combined 10,000 pallet position storage area for temperature sensitive pharma cargo. Our pharma operations at our Dubai hub have been certified as compliant to EU GDP standards.

Cool Dollies: We have an extensive fleet of close to 50 cool dollies in Dubai, dedicated for the transport of pharma. Our main deck and lower deck Emirates Pharma Cool Dollies act like giant mobile refrigerators, preventing temperature excursions for sensitive shipments on the ramp; this is done by maintaining a constant temperature when cargo is being moved from the cargo terminal to the aircraft, or the other way around. Our Cool Dollies are capable of maintaining temperatures as low as -20˚C.

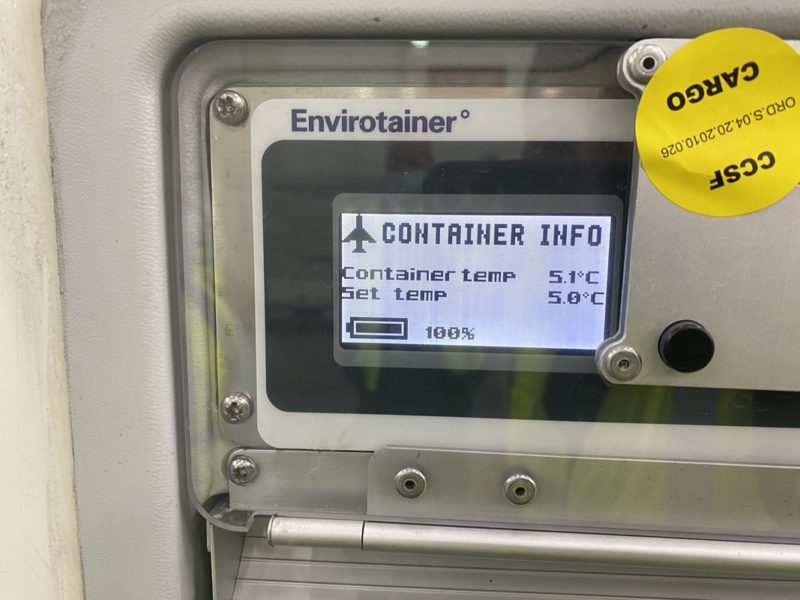

Specialised containers: Where pharma or vaccine shipments need to be maintained at constant low temperatures, we work with all the market leaders in specialised containers including: Envirotainer, CSafe, va-Q-tec and SkyCell to ensure that there is no temperature deviation. Some of these containers are capable of maintaining extremely low temperatures for several days, even when disconnected from a power source, thereby ensuring the integrity of the pharma product being transported.

Thermal covers: We have a range of specially designed thermal covers that we’ve developed in collaboration with DuPont. They’re called White Covers and you have three different types: White Cover, White Cover Active and White Cover Xtreme. They offer differing levels of protection for pharma cargo from heat, cold, dust and humidity.

We are able to offer an unbroken cool chain during the time the cargo is in our aircraft, or transiting through Dubai. However, it is important that the focus on unbroken cool chain is maintained; not just in our aircraft or at our hub in Dubai, but from the origin airport to the destination airport.

3. Some vaccines need -70˚C in storage. How can air transport handle that?

In case of pharma cargo, which needs to be maintained at very low temperatures such as -70˚C, the manufacturer of the pharmaceutical will provide a passive packaging for the shipment, this will maintain the cargo at the required temperature. The passive packaging normally includes a coolant, such as dry ice. The shipment in the passive packaging can then be transported, being kept at a normal Cool Room Temperature of 15-25˚C by Emirates SkyCargo.

4. When do you expect the first shipment of vaccine?

We have already undertaken transportation of COVID-19 vaccines for trial and testing purposes.

5. With the current downturn in commercial belly cargo space availability, do you see a huge limitation in transporting both cargo and vaccines?

As part of our normal business, we transport cargo on dedicated freighter aircraft and also in the belly hold of our passenger flights. The latter plays quite a key role as prior to COVID-19, around 70% of the total freight we transported were carried on passenger aircraft. When COVID-19 forced the complete suspension of passenger flight operations in late March, this entire capacity suddenly was no longer available to us.

At this point of time, worldwide, there was still demand for the transportation of cargo, especially for urgent medical and PPE supplies. In order to meet this demand, we started operating our Boeing 777-300ER passenger aircraft as cargo only aircraft. Our Boeing 777-300ERs are widebody aircraft with around 40-50 tonnes of belly hold capacity (without passengers). We were able to deploy these and increase our destination network from about 35 (served by our 11 Boeing 777 freighters) at the end of March to around 50 by April. Over the next two months, we further increased our network to more than 75 destinations. Currently we’re flying cargo to 135 destinations across six continents.

In the meantime, we also came up with other innovative solutions to increase the amount of air cargo capacity. This included loading cargo on the seats of passenger aircraft and in the overhead bins.

In the month of June, we also removed seats in Economy Class from 10 Boeing 777-300ER aircraft; we did this to convert them into what we like to call ‘mini-freighters’. These aircraft continue to operate across our global network and are an important part of our cargo offering.

6. Will A380 play more role in transporting cargo and vaccine?

It is possible to use the A380 aircraft to transport vaccines. We recently operated our Airbus A380 aircraft on cargo charter operations, transporting medical supplies. The cargo capacity of the aircraft was optimised to around 50 tonnes of cargo in the belly hold. The decision on utilising the A380 aircraft will depend on the demand, routing and capacity requirements of the vaccine transport.