During the Airbus Summit in Toulouse, an announcement was made regarding the "Wing of Tomorrow" program to explore new manufacturing and assembly techniques, with the goal of making aviation more sustainable.

Wing of Tomorrow program

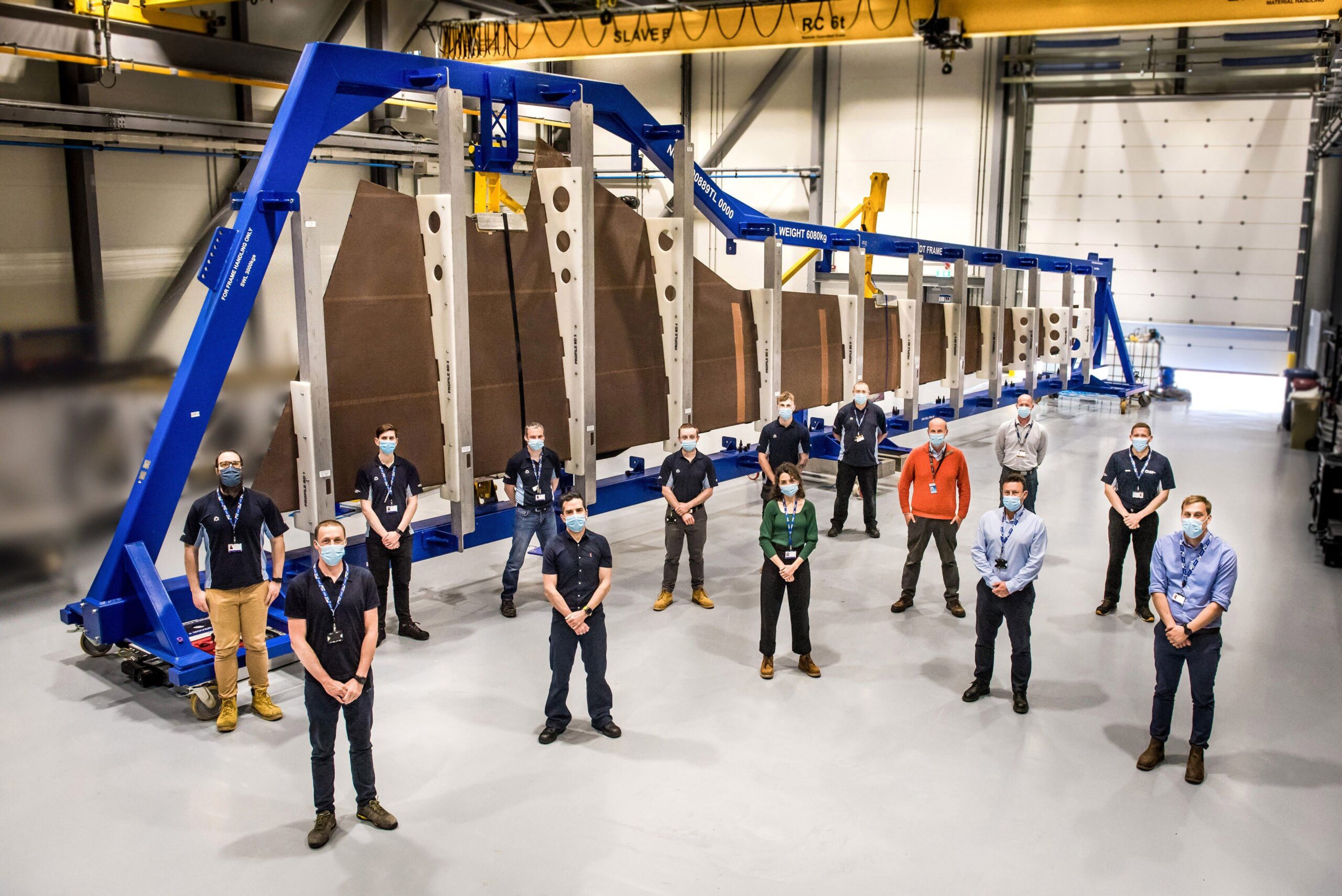

‘Wing of Tomorrow’ is a major Airbus research and technology program that has reached a key milestone with the assembly of its first full-size wing prototype. The new wing demonstrator will bring together more than 100 new technologies, to explore new manufacturing and assembly techniques with the goal of making aviation more sustainable.

The Wing of Tomorrow program will not only test the latest composite materials and new technologies in aerodynamics and wing architecture but, more importantly, explore how wing manufacturing and industrialisation can be improved to meet future demand as the sector emerges from the pandemic.

Three full-size prototype wings will be manufactured in total:

- One will be used to understand systems integration

- A second will be structurally tested to compare against computer modelling

- A third will be assembled to test scaling-up production and compare against industrial modelling

Sabine Klauke, Airbus Chief Technical Officer, said: “Wing of Tomorrow, a crucial part of Airbus’ R&T portfolio, will help us assess the industrial feasibility of future wing production. High-performing wing technology is one of several solutions - alongside sustainable aviation fuels and hydrogen - we can implement to contribute to aviation’s decarbonisation ambition. Wing of Tomorrow is also an example of how large-scale industry collaboration will be critical to achieving our sector’s agenda for a more sustainable future.”

Wing of Tomorrow, part-funded by the UK’s Aerospace Technology Institute, is a fully transnational Airbus program involving global partners and teams across Airbus’ European sites, including Bremen in Germany where the ‘Wing Moveables’ team is based.

Sub-assembly of the complex wing cover took place at Airbus’ Filton site, England, having been manufactured at the National Composite Centre in Bristol. The wing cover and a major component from GKN Aerospace - the Fixed Trailing Edge - were delivered to the Advanced Manufacturing Research Centre, Wales, facility on Airbus’ wing-production plant in Broughton, Flintshire, for assembly to begin.