Airbus teases folding wings for future aircraft

Aircraft manufacturing is a competitive industry. Manufacturers aggressively compete to build and deliver the best and most aircraft they can. In today’s world where every last order is make or break, manufacturers push to get every drop of performance out of their product, hence the interesting new features that are starting to appear.

One of these recently introduced features if the folding wing. Now this technology has been around for a long time but over the last few years we’ve seen developments from Boeing regarding the 777x and its folding wing. This will be the first ever commercial jetliner to offer folding wings.

So what do folding wings have to offer?

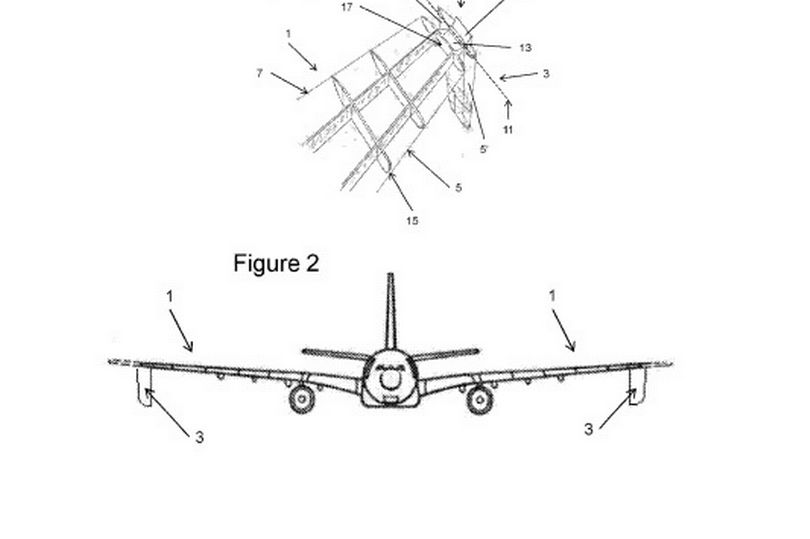

Folding wings allow manufacturers to increase the wingspan of an aircraft while retaining the ability to park in a small space. The idea is that before takeoff, the pilots will deploy the wings just like flaps. Upon landing, the wings would be folded up or down and allow the aircraft to park in gate spaces or hangars.

Increased wingspan means a reduction in drag and better aerodynamics. It has a chain reaction effect on any aircraft. A good example is a glider. The cabin area is tiny compared to the enormous wings. This allows for greater lift and reduced drag, allowing it to stay in the air for long periods of time.

Airbus’ take on the folding wing

Airbus‘ Filton wing facility is where the magic happens. Wings are designed, tested and built there, and the factory holds many dedicated engineering teams under its belt.

“The Wing of the Future” is currently being designed at this very facility. Using advanced 3D modelling. virtual reality and new methods of team contributions, Airbus’ Filton plant has arranged a wing for future narrow body aircraft such as A320 family additions or a totally new family.

Typically, the A320 family has been quite limited in terms of wing performance. With the Boeing “797” slowly entering reality, Airbus needs to fight with an aircraft that’s new enough to compete. With this in mind, neither of the companies want to build a super advanced aircraft like the 787 and A350. Boeing has stated many times that the aircraft will not include groundbreaking features and Airbus is already stating the A321LR is enough.

Airlines however are not sold on this, hence the recent developments from both sides.

The proposed A320 family addition Airbus is studying is expected to feature this new folding wing, which Filton says will be in production within the next 10 years.

Airbus and the wing design team are targeting a wingspan of around 40-44 meters – a significant increase from the A320s 36 meters.

Engineers are currently working on performance figures and have so far agreed on a 12% reduction in drag.

Anthony Meisner, one of the team members for the project, explained the benefits of this reduction to an aircraft in the following statement to The Guardian:

“It means that you don’t need as much thrust to push it through the air, which means you can reduce engine weight. It’s a snowball effect in terms of aircraft design.”

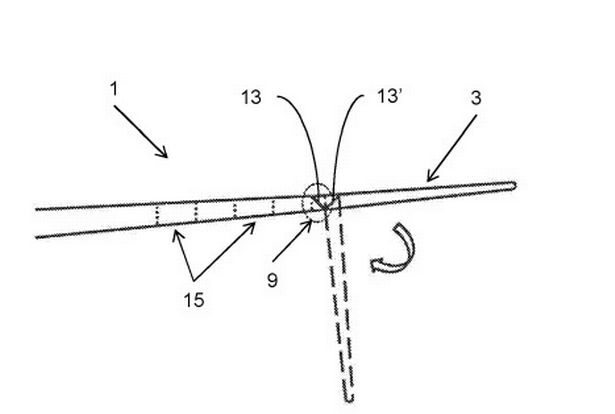

Interestingly enough, despite the folding wing being similar to the Boeing 777x, Airbus has elected to go for a downward facing design.

The idea of having the fold pointing down means lighter locking systems and mounting points in the wing. Why? Because as lift is generated, it forces the wing into place. If the navigation lights are positioned on the wing then there will be easier maintenance if one of them fails.

However, there is one issue that has been brought up and that’s the ground clearance. The wing fold would be limited to whatever the height is at the end of the wing and whether it will scrape the ground or any vehicles in the area. The role of an engineer is to overcome a problem but nothing has been mentioned about what’s planned for this.

Wing manufacturing processes will also have to be overhauled. The new technology, production ramp-ups and the use of composites means new equipment and possibly new factory locations.

With Brexit pushing Airbus into panic mode, countries around the world are already in discussions to take over wing manufacturing should Airbus walk out of the UK.

Spain has large amounts of expertise in composite parts for Airbus and is currently a location on the board. Other countries include Germany, France, China and the United States.

With Airbus indicating the wing will be in production within the next 10 years, it begs the question: