The long awaited maiden flight of the first Boeing 777X will be delayed after engineers identified problems with the General Electric engines fitted to the aircraft.

Powered by two GE9X engines, the first and largest variant of the 777X, the 777-9, was scheduled to fly on the 26th of June according to Emirates, however Boeing has pushed back the flight to sometime before the end of the year.

Sitting on the flightline in Everett, Washington are the first two flight test aircraft which are undergoing systems testing prior to launching their flight test campaigns.

N779XW, the first test frame, was performing engine tests when Boeing identified an anomaly within the engines, forcing them to immediately halt tests.

777-9 INITIAL ENGINE RUN!! She’s ALIVE!!!! N779XW had her first engine run today producing smoke – and excitement from those watching 👍👏😍. #b7779 #boeing7779 #777x #b777x #boeing777x #n779xw #boeing pic.twitter.com/FskLnvYol9— Katie Bailey (@KPAE_Spotter) May 29, 2019

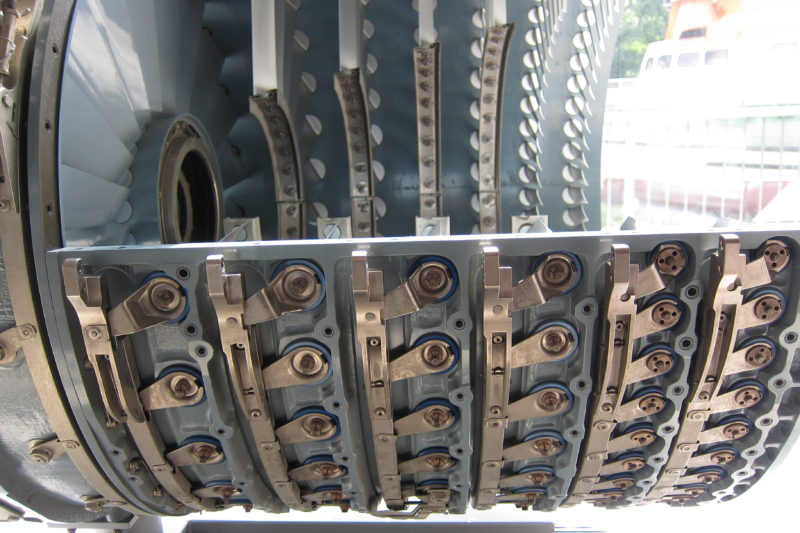

Inspection of the engines identified problems with the Variable Stator Vanes (VSVs), which are responsible for modulating airflow through the compressor section of the engine.

Powered using pneumatic or fluid means, the lever arms that control the VSVs have been subject to redesign earlier in the GE9X test program, which caused minor delivery delays.

Analyzing data from the engine, General Electric has also located an opportunity to make some minor refinements to the front of the compressor section to increase its lifespan.

Certification of the engine will continue, with General Electric aiming for the end of the year. According to Flight Global, 85% of the certification campaign has been completed, including bird ingestion, blade-off testing and weather testing.

The only remaining tests are emissions and block testing, which include running the engine 25 times for a period of six hours with the exhaust gas temperature (EGT), fan speed and core speed at maximum “redline” indications.

With a fan diameter of 3.4 meters (134in) compiled using 16 carbon fiber, titanium reinforced blades, the GE9X is the world’s largest turbofan engine, trumping the GE90, as seen in the following diagram produced by Jon Ostrower at The Air Current.

Despite its enormous size, the engine produces less thrust than the GE90-115B found on the Boeing 777-300ER.

| Engine | Thrust (lbf) | Bypass Ratio | Fan Diameter (cm/in) |

| GE9X-105B1A | 105,000 | 10:1 | 340cm/134 in |

| GE90-115B | 115,540 | 9:1 | 330cm/128 in |

Using 11 compressor stages instead of 9 and 10 found on previous engines of a common family (GE90, GEnx), the GE9X features an overall pressure ratio of 60:1, with the high-pressure compressor boasting a 27:1 ratio.

Combined with the third generation, twin-annular pre-swirl (TAPS) combustor and ceramic matrix composite materials, the GE9X is set to be the worlds most efficient and advanced commercial turbofan engine – a title the Rolls-Royce Trent XWB that powers the Airbus A350 currently holds.

For those interested in the sound of the engine, watch the following video:

General Electric has a game changer of an engine for the Boeing 777X. With the advancements in technology, snags in the testing and certification process is to be expected, however with ongoing 737 MAX woes, Boeing would have hoped the 777X program would operate smoothly.

Emirates and Lufthansa are showing concern with the advertised entry into service dates and are expressing thoughts bearing late 2020/early 2021 as the delivery date for the first aircraft.