The European Aviation Safety Agency (EASA) has presented Boeing with five major requirements that need to be addressed, before the 737 MAX returns to service.

Reported by Bloomberg on the 6th of July 2019, the article notes the aircraft will not be allowed to fly again until the requirements are addressed and are tested accordingly.

The five requirements the European Aviation Safety Agency have listed so far are as follows:

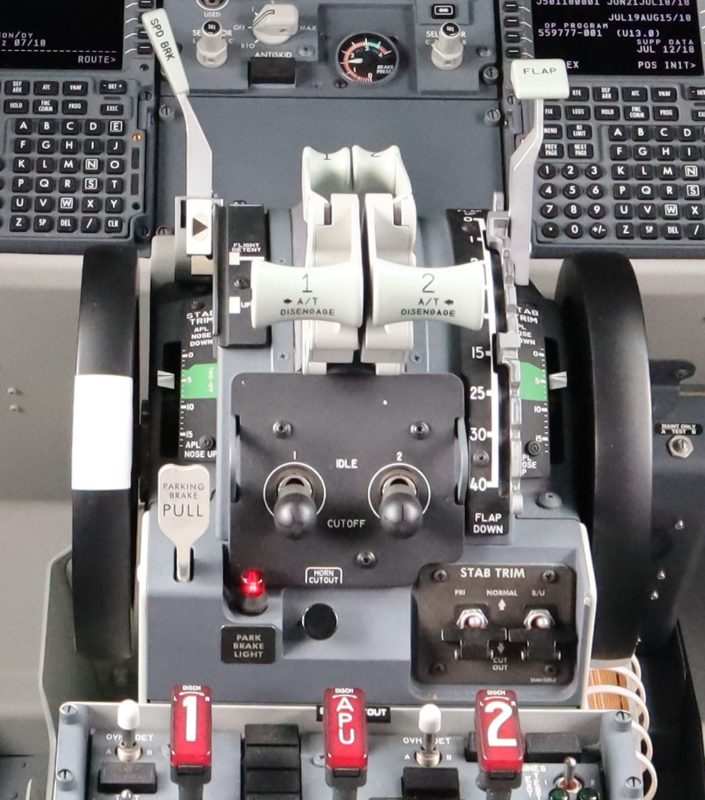

- Reduce the difficulty manually turning the trim wheel

- Address the unreliability of Angle of Attack sensors

- Address the training situation

- Investigate software issues with a lagging microprocessor

However the biggest and newest to join the list of problems involves the autopilot system in the aircraft, which reportedly fails to disconnect in some emergency scenarios.

Investigations have concluded that pilots who encounter a stall scenario relating to the Manoeuvring Characteristics Augmentation System (MCAS) or similar flight control emergencies have difficulty disconnecting the autopilot.

Bloomberg notes the autopilot doesn’t completely disconnect. This could mean the system is designed in a way to work with MCAS so closely it still believes it has greater authority than the pilots.

Having to redesign, or modify, the existing autopilot system of new production and grounded aircraft would take enormous amounts of time and resources.

Adding to the woes is the latest software update which was expected to address the original MCAS problem, however it was rejected as errors were identified during simulator testing.

Past and present engineers within the aviation industry have flagged the aircraft as unsafe to fly because it is not a software problem, it is a structural problem that required the MCAS system in the first place.

A redesign of the engine position on the aircraft would cost a ridiculous amount of money and would likely render the grounded aircraft useless. Flight testing and new production methods would have to be conducted, leaving the idea in the scrap bin.

Despite this the idea to add or redesign hardware hasn’t been completely disregarded as EASA director Patrick Ky said, retrofitting additional hardware relating to the angle of attack sensors was still an option.

This alone would still be expensive and time consuming for Boeing. To this day, we still do not know when the aircraft will be flying again. We’ve seen it multiple times with airlines who are constantly shuffling their 737 MAX schedule around.

EASA is conducting one of the most thorough investigations of the aircraft design and has been focusing on the differences between previous 737 flight controls and the 737 MAX.

Due to the heat surrounding the Federal Aviation Administration, it is likely the world will take EASAs word first.

However, in an effort to regain passenger confidence, EASA along with the FAA, Canada and Brazil will jointly sign an agreement to permit the aircraft to fly again.

This will depend on whether the Boeing and the FAA accept and address EASAs requirements.

The current estimated return time to service is September, however many remain sceptical as this timeline includes the software update regarding the lagging processor, test flying, joint re-certification, repairs and flight resumption work conducted by airlines.

When do you think the aircraft will return to service?