The Federal Aviation Administration (FAA) has issued today a new airworthiness directive (AD) for the International Aero Engines AG (IAE) V2500 engine.

The IAE V2500 powers the Airbus A320ceo family, Boeing/McDonnell Douglas MD-90 and Embraer KC-390.

Previous Problems

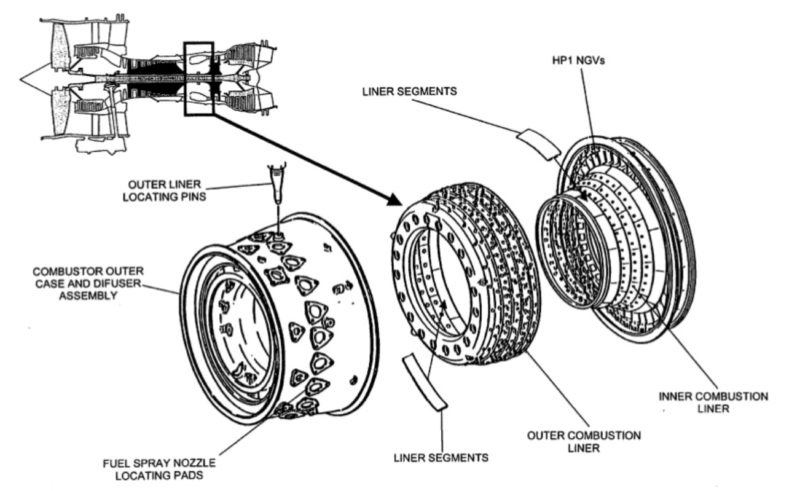

In the previous AD the FAA reported that cracks had been found at the diffuser case M-flange, during the overhaul inspection.

As a result, it was required initial and repetitive borescope inspections of the diffuser case M-flange; if there were any failures detected during these inspections, then replacement was needed.

Required Actions

The FAA issued this AD after a report of a manufacturing quality issue, that could impact the expected life span of the diffuser case assembly.

It requires the removal of the affected diffuser case assembly from service, the part must be replaced with one which is eligible for installation.

This AD concerns the following turbofan engines: V2500-A1, V2522-A5, V2524-A5, V2525-D5, V2527-A5, V2527E-A5, V2527M-A5, V2528-D5, V2530-A5, V2531-E5, and V2533-A5 with diffuser case assembly serial number PGGUBB8267, PGGUBB8271, PGGUA95825, PGGUA95827 or PGGUBB8264, installed.

According to the FAA, this should be done at the next engine shop visit after the effective date – May 29th – or before accumulating 10,000 cycles since new, whichever occurs first.

If the situation is not addressed, it could result in: the uncontained release of the diffuser case assembly, damaging the engine and consequentially the aircraft.

For the removal of the diffuser case assembly, the FAA estimates that it will take around 70 hours. At a cost of $85 per hour, each engine will cost $5,950 plus a part cost of $250,000 making a total of $255,950.

Article Source: FAA ; Feature Image: Christopher Payne for The New York Times

Craig, I had the same thought. He’s at 1% now but 66% is unacceptable?? Of course, his is an airline I wouldn’t fly if it was free.

Well now, let’s put Mr. O’Leary on a packed plane in the middle seat… will he or won’t he set aloft? Just who is the 800 pound idiot in the cabin? If you don’t break even with a 66% load factor, a moderate increase in tariffs might ease the burden…and actually be appreciated by your staunch frugal customers. Ask them..at what price is your safety worth? And for that matter if there isn’t a strong demand going forward…this may all be a moot point?!?