The Federal Aviation Administration (FAA) has issued a new Airworthiness Directive (AD) for the General Electric GE90, that powers the Boeing 777.

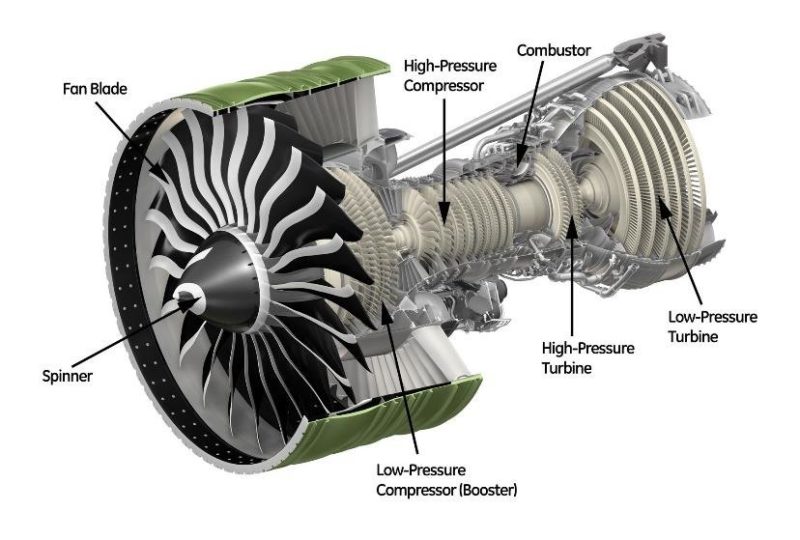

This AD concerns the GE90-110B1 and GE90-115B; used on the B777-300ER – turbofan engines, with a certain interstage high-pressure turbine (HPT) rotor seal installed. Both engines can also be used on the 777-200LR and the 777F.

Previous Problems

The FAA has explained that, on 20th October 2019, a Boeing 777-300ER suffered an uncontained interstage high-pressure turbine (HPT) rotor seal failure, resulting in an aborted takeoff.

According to The Aviation Herald, on the same day, a Thai Airways B777-300 (HS-TKL) performing flight TG-970 from Bangkok (Thailand) to Zurich (Switzerland) suffered the same incident described by the FAA.

As a result, debris impacted the aircraft fuselage and the other engine.

Required Actions

This AD requires initial and repetitive ultrasonic inspections (USIs) of the interstage HPT rotor seal. Depending on the results of the inspections, a possible replacement may be required; this replacement must be with one which is rightly eligible for installation.

The AD also requires the removal of the interstage HPT rotor seal, at the next engine shop visit.

For the purpose of this AD, the FAA has explained that an “engine shop visit” is the induction of an engine into the shop for maintenance involving the separation of pairs of major mating engine flanges.

The AD is effective as of May 27th 2020. The FAA has also explained that, after the initial USI, this procedure must be repeated within every 100 cycles since the last inspection.

“The FAA considers this AD an interim action. The root cause of the interstage HPT rotor seal failure is still being investigated and the FAA will consider further rulemaking, depending on the results of the investigation”

If the situation is not addressed, it could result in an uncontained interstage HPT rotor seal failure and a release of high-energy debris; damaging the engine and consequentially the aircraft.

Costs

To perform an ultrasonic inspection of the interstage HPT rotor seal, the FAA estimates that it will take 2 hours, at a cost of $85 per hour, and each engine will cost $170.

However if the replacement of the interstage HPT rotor seal is needed, the cost will of course be much higher. The FAA estimates that it will take around 100 hours, at a cost of $85 per hour, with each engine costing $8,500 plus a part cost of $540,000, making a total of $548,500.

Feature Image: Alec Wilson