On 20th August 2007, China Airlines Flight 120, a Boeing 737-800 caught fire and exploded in Japan after a bolt came loose from the slat track which eventually punctured the right-wing fuel tank.

Flight Details

China Airlines Boeing 737-800 – registered B-18616 was operating flight CI120 from Taipei to Naha with 157 passengers and 8 crew members on board. Flight 120 landed safely at Naha Airport after a flight time of one hour and six minutes.

The crew taxied the aircraft to the gate, de-configuring the aircraft as per the after-landing checklist. However, after the pilots shut off the engines and the passengers were prepared to disembark, a fire erupted in engine number 2.

Ground crew members noticed the flames coming out of the engine and informed the air traffic controller. Subsequently, the controller informed the captain about the situation and the captain ordered an emergency evacuation saying, “Passenger Evacuation! Passenger Evacuation!”

Soon after performing the evacuation procedures together with the First Officer, the captain made an announcement in Chinese, saying, “Cabin crew, proceed with emergency evacuation immediately after all passengers have been evacuated from the aircraft.”

Miraculously, everyone on board managed to disembark the aircraft through the four hatches using slides just before the plane exploded. After ensuring that all those on board disembarked the aircraft, the Captain and First Officer exited the aircraft through the cockpit window. As seen in the video below, the pilots attempted to exit the cockpit using the escape rope but the F/O ripped off the rope when the number 2 engine and right-wing fuel tanks exploded. The captain jumped from the window without using the rope. Besides some minor injuries, all passengers and crew members were evacuated safely.

The aircraft was badly damaged and destroyed by the fire, leaving only part of the airframe intact. The fuselage was bent lengthwise at the part immediately aft of the wing roots. The left-wing, which was almost entirely burned and had lost its original shape, laid over the engine resting on the ground. The wing portion between the engine and fuselage was destroyed by the explosion of the fuel tank and the burnt main landing gear was tilted forward. The right main landing gear was burned and stood upright, while both the engines and the wing tip were resting on the ground.

The No. 1 (left) engine was entirely burned, while the fuselage-side cowling of the No. 2 (right) engine was consumed by the fire and the engine itself was partially burned at the fuselage-side, fan sections. The aircraft was written off due to the extensive damage.

ARAIC Investigation

Following the incident, the Aircraft and Railway Accidents Investigation Commission of Japan (ARAIC) designated an investigator-in-charge and other investigators to investigate the accident. Accredited representatives of the National Transportation Safety Board (NTSB) and Taiwanese Aviation Safety Council also participated in the investigation including the on-site investigation at Naha Airport. The on-site investigation found that the fuel had leaked out from a puncture hole found in a slat’s track.

The flight captain stated that they received no fire indication during the flight or after the landing. The recording in the cockpit voice recorder also clarified that the pilots did not observe any abnormalities before the incident.

There was no fire alarm or the like during the pre-flight check of the aircraft, during the flight or after the landing. I found no indication of abnormal fuel consumption during the flight, either. Everything was normal until the accident.

Captain, China Airlines Flight 120

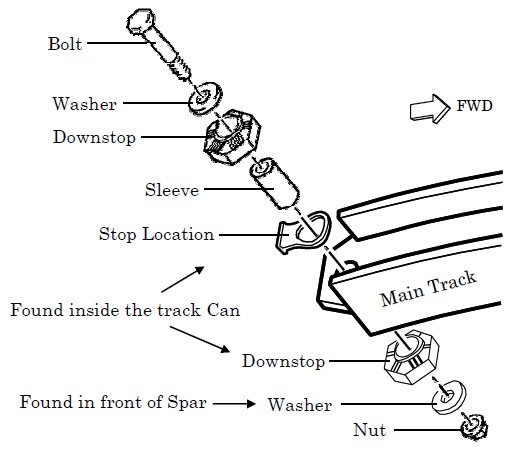

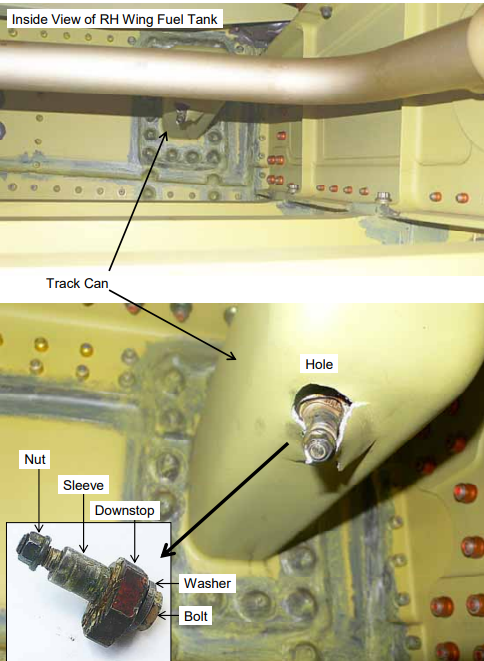

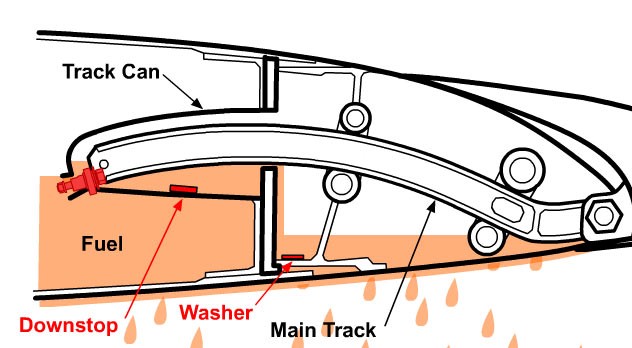

Digging into the incident, investigators found that an incorrectly installed bolt in the right-wing of the aircraft’s No 5 slat down-stop had worked itself loose. The bolt was torqued without the requisite washer in place during scheduled maintenance some six weeks before the incident (The aircraft had undergone scheduled maintenance (C Check) from July 6 to 13, 2007). As a result, the nut worked itself loose and caused the entire down-stop assembly to detach, which eventually fell onto the track of the slat-can assembly during the ground movement at Naha Airport.

During taxiing, the slat track moved back into the track can, pushing the detached assembly ahead of it. The powerful hydraulic slat actuator moved the slat track into the fully retracted position, eventually shoving the downstop bolt straight through the wall of the track can, thus puncturing the fuel tank.

As a result, the fuel leaked out through the hole which measured 2-3 centimeters in diameter. A fire started when the volatile jet fuel came into contact with high-temperature areas on the right engine. Much of the fuel burned out during explosions, as there was no sign of fuel leakage during taxiing. Investigators discovered that the cause of this near-disaster fire and explosion was a single missing washer. The washer was found lying just below the opening provided in the front end of the wing forward spar, through which the main track passed.

Temporary Grounding and Aftermaths

Following the incident, the Republic of China Civil Aeronautics Administration grounded the entire fleet of Boeing 737-800s of China Airlines, Mandarin Airlines, and the Republic of China Air Force for further inspection of the fuel systems. Similarly, the Japanese Civil Aviation Bureau also asked the Japanese operators of 737-700 and 737-800 aircraft to inspect their aircraft. However, no irregularities were found and the aircraft returned to service.

In its final report, the ARAIC recommended the US Federal Aviation Administration supervise Boeing to ensure that maintenance instructions take into account the conditions under which the work must be performed. A similar recommendation was also sent to the Civil Aviation Bureau of Japan.

Cover Image: AP