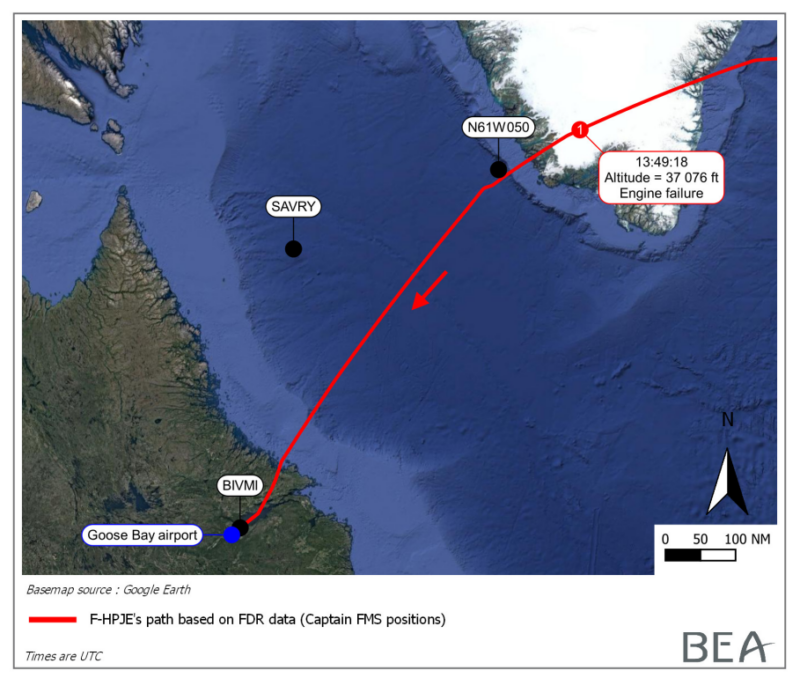

On September 30, 2017, an Air France Airbus A380 operating flight AF066 from Paris Charles de Gaulle to Los Angeles suffered an uncontained engine failure while cruising over southern Greenland.

After the failure, the aircraft’s heading increased by three degrees to the right in three seconds, and there were vibrations in the airframe for around four seconds. However, despite the engine failure, the flight crew maintained full control of the aircraft and made a safe emergency landing at a remote Canadian airport.

Flight Details

The Airbus A380-800 with registration F-HPJE was performing flight AF066 from Paris CDG to Los Angeles (LAX) with 497 passengers and 24 crew members. The captain in command had logged more than 19,000 flight hours, including 3,249 hours in the A380. During the take-off, the first officer was the pilot flying (PF) and the captain was PM.

Departing Paris Charles de Gaulle at 09:50 local time, the flight proceeded uneventfully for a couple of hours. The crew adjusted the cruising levels several times during the transatlantic crossing, ultimately stabilizing at FL370 by 11:14 UTC.

Subsequently, at 13:48 UTC, while flying over the remote icy terrain about 100 nautical miles southeast of Greenland, the crew requested to climb to FL380. Clearance was granted, and the engines began spooling up — their low-pressure compressor and turbine rotation speeds (N1) rising from 98% to 107%, close to the redline limit.

One minute later, Disaster Struck!

Roughly five hours into the flight, while cruising at 37,000 feet, the aircraft’s number 4 engine (the rightmost engine) stalled, ejecting its front fan and cowling midair. The titanium fan hub fractured into at least three pieces due to a previously undetected cold dwell fatigue crack, ejecting massive fragments from the engine.

Two major parts were launched violently, one upward, one downward, destroying the forward cowling and separating the entire air inlet, which fell onto Greenland’s ice sheet. Although debris hit the wing and fuselage, critical systems remained intact.

The aircraft shuddered violently. The crew heard a loud bang, the flight path skewed slightly to the right, and the airframe shook for about four seconds. The Electronic Centralized Aircraft Monitoring (ECAM) system displayed an “ENG 4 STALL” warning.

Following the engine failure, the captain took manual control, engaged autopilot 1 briefly, and ordered the ECAM engine shutdown checklist. Engine 4 was set to idle, and an automatic shutdown followed. FO/2 confirmed the shutdown by pressing the Engine 4 Master and Fire pushbuttons.

From the cockpit, the crew had no visibility of the engine damage. It was only when a cabin crew member brought up a passenger’s smartphone photo that the scale of destruction became clear. FO/1 returned to the flight deck to assist and personally inspected the engine from the upper deck, noting damage to the slats and minor vibrations in the flaps. After the inspection, the crew began evaluating their options for diversion.

Diversion to Goose Bay

Although the aircraft initially maintained level flight at FL370, airspeed began to fall from 277 knots to 258 knots in the first minute and a half after the engine failure. Aware of the gradual deceleration, the captain initiated a drift-down to the engine-out maximum altitude (EO MAX FL 346) computed by the flight management system. The crew had to pause ECAM procedures during each descent step, stabilizing at FL360, then FL350, FL330, FL310, and finally at FL270, where a safe balance between thrust and speed was reached.

The three remaining engines were pushed to Maximum Continuous Thrust (MCT) to maintain performance. At FL270, the aircraft stabilized at 279 knots indicated airspeed, and a safe cruise was maintained.

About five minutes into the descent, Gander Oceanic Control noted the aircraft’s deviation from its cleared altitude and sent a CPDLC message: “ATC NOW SHOWS YOU FL330. IS THERE A PROBLEM?” Moments later, Air France Flight 66 declared a Mayday, both via relay from another aircraft and through direct radio contact on 132.37 MHz. Gander ATC responded swiftly and began assisting with route clearance.

The crew evaluated their diversion options in coordination with Air France’s operations center. While Kangerlussuaq Airport in Greenland was closer, the crew chose to divert to CFB Goose Bay (YYR) in Newfoundland and Labrador, Canada. Factors influencing this decision included the captain’s prior experience with Goose Bay, its approach environment, and its longer, better-equipped runway, deemed more suitable for handling an A380 in abnormal conditions.

Landing in Goose Bay

As the aircraft neared Goose Bay, it was cleared for the RNAV GNSS approach to Runway 26. At 1,000 feet above ground level, the captain disengaged the autopilot and the flight director and completed a manual landing. At 15:42 UTC, Air France flight 66 touched down smoothly. While taxiing in Goose Bay, the aircraft stopped several times as airport staff removed engine debris found along the runway.

Although safe on the ground, the saga wasn’t quite over. Goose Bay, a remote military airport, was not equipped to handle 500+ international passengers. Immigration capacity was overwhelmed, and accommodation was limited. While some passengers were allowed into the terminal, most remained onboard. Meals were served on the aircraft, and the captain personally addressed the passengers in groups of 50, explaining the situation and the next steps.

Alternative flights were arranged, and by 08:10 on October 1, all passengers had disembarked, nearly 17 hours after landing. Despite the extraordinary circumstances, there were no injuries, and the crew’s calm, decisive actions ensured everyone reached safety.

Aircraft Damage

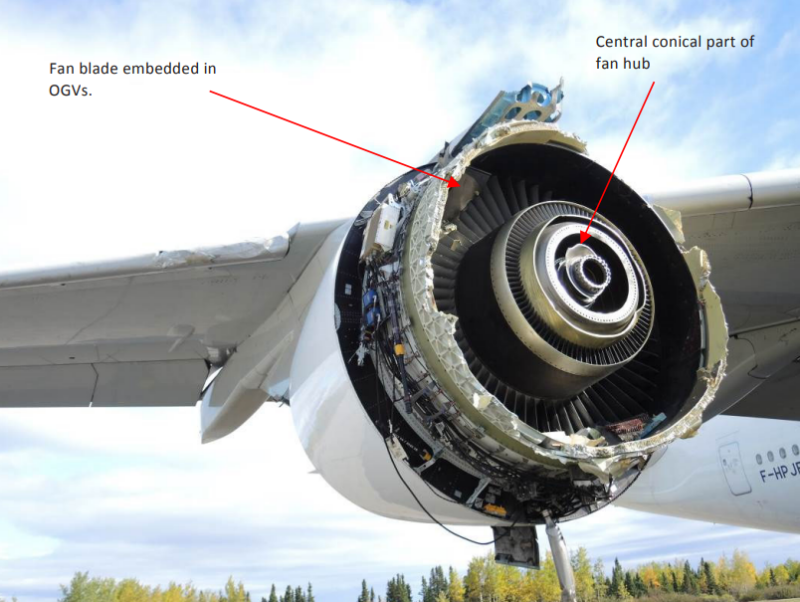

Following the emergency landing at Goose Bay, initial inspections of Air France A380 revealed extensive damage to the number 4 engine and several areas of the right wing. Despite the severity of the in-flight engine failure, the aircraft had landed safely, and no structural damage had compromised the cabin or critical control systems.

Most of the engine’s forward structure had been completely destroyed or torn away. Missing components included the fan hub’s major parts, nearly all of the fan blades, the air inlet cone, and both engine cowlings. Over 2.5 meters of the air inlet section had detached during flight.

Moreover, inspectors noted that large portions of the fan case isogrid had disintegrated and peeled outward in a petaled pattern between the 4 o’clock and 6 o’clock positions and the 8 o’clock and 12 o’clock positions. The central conical section of the fan hub remained attached to the engine’s low-pressure turbine shaft, but the hub itself had fractured along nearly its entire circumference and was locked in place, unable to rotate. The fracture surface exhibited a matte, granular texture, consistent with cold dwell fatigue, a rare type of failure initiated by slow crack growth under low stress at high altitude.

Debris from the engine was found embedded within the engine nacelle and on the runway, including fan blade fragments, pieces of the front cone, structural honeycomb panels, and even attachment bolts. One fan blade fragment was discovered lodged within the outlet guide vanes (OGVs), which highlights the extreme internal forces at play during the breakup.

Wing and Airframe Damage

While the uncontained failure sent large engine fragments flying in multiple directions, the A380’s structure held firm. Several impact marks and deformations were identified on the wing surface and the nacelle pylon supporting engine No. 4, indicating contact with detached engine parts.

Damage extended to the leading edge slats, wing flaps, and aileron assemblies. Additionally, the flap rail fairings and portions of the trimmable horizontal stabilizer showed signs of minor impact. Despite this, none of the debris penetrated the cabin or fuel tanks, and no loss of flight control systems occurred.

According to the final accident report, no other areas of the aircraft were affected beyond those detailed above. The cabin remained sealed and undamaged, and there was no reported injury to passengers or crew. While the damage was substantial, it remained localized to the engine structure and surrounding wing surfaces.

Investigation and Findings

The investigation was led by France’s BEA (Bureau d’Enquêtes et d’Analyses) with support from the NTSB, Transport Canada, Airbus, and Engine Alliance (a joint venture between GE and Pratt & Whitney).

The factors likely to have contributed to the accident include:

- Engine designers’/manufacturers’ lack of knowledge of the cold dwell fatigue phenomenon in the titanium alloy, Ti-6-4;

- Absence of instructions from the certification bodies about taking into account macro-zones (i.e., colony of similarly oriented alpha grains) and the cold dwell fatigue phenomenon in the critical parts of an engine, when demonstrating conformity;

- Absence of non-destructive means to detect the presence of unusual macro-zones in titanium alloy parts;

- An increase in the risk of having large macro-zones with increased intensity in large Ti-6-4 forgings due to bigger engines, and in particular, bigger fans.

Moreover, the investigation into the failure later pinpointed the root cause as a subsurface manufacturing anomaly in the titanium alloy fan hub, which had developed a fatigue crack that grew slowly over time.

The incident prompted a wide-reaching safety response from Airbus, Engine Alliance, and regulatory authorities, leading to emergency inspections of similar engine models installed on other A380s worldwide.

Aftermaths

Air France initially considered ferrying the A380 back to Europe with a replacement engine shell, one that was inoperable and used solely for weight and balance purposes. Due to the unique configuration and safety considerations of flying with a non-functional engine, such a flight required special operating procedures and simulator training by the flight crew.

However, this plan was later revised. On December 6, 2017, the aircraft was successfully ferried from Goose Bay Airport back to Paris Charles de Gaulle Airport using four fully operational engines, with an Air France crew at the controls.

Meanwhile, the damaged engine was flown to East Midlands Airport in the United Kingdom, where General Electric examined the engine from the 23rd to the 25th of November 2017. This analysis became a key part of the wider investigation into the cause of the fan hub failure.

After months of inspections and structural repairs, F-HPJE was returned to commercial service on January 15, 2018. It remained in operation until May 2020, when Air France officially retired its A380 fleet amid the dramatic downturn in air travel caused by the COVID-19 pandemic. The aircraft’s final flight took place on April 28, 2020, when it was ferried from Paris to Tarbes–Lourdes–Pyrénées Airport (AF371V), where it joined two other retired Air France A380s and several ex-Singapore Airlines units in long-term storage.

In a notable postscript, the missing fan hub fragment, which had separated from engine No. 4 and fallen onto the Greenland ice sheet, was finally recovered after a lengthy and complex operation. The search effort spanned four phases over 20 months and culminated in a successful aerial and ground recovery on 29–30 June 2019, providing crucial forensic evidence for investigators.

Sam Chui, you are the best, There are other vlogs that deal with air travel, particularly the husband-and-wife team type of review. This fine as far as it goes. However, yours is the only one that encompasses all the aspects we need. You give use the service reviews, and the technical data, and I just love your enthusiasm about air travel. Love you Sam.