In November 2009, Boeing broke ground in North Charleston, South Carolina, on a revolutionary manufacturing facility for the B787 Dreamliner.

Recently, in conjunction with the World's First B787-10 delivery, Boeing have given a tour of its South Carolina facility. I was able to visit the final assembly, midbody, aftbody plant and interior responsibility center.

Tour Video

Final Assembly

The 787 final assembly building opened in 2011, provide expanded production and delivery capability to help the company fulfill orders for 787-8 and 787-9 from more than 60 customers. worldwide. The first 787 Dreamliner built in South Carolina rolled out in April 2012. By the end of the decade, Boeing plans to increase total production to 14 Dreamliners per month.

In final assembly, the three main fuselage sections, wings, horizontal stabilizer, vertical fin, and tailcone of the 787 are integrated. Teammates then install the engines, landing gear and other systems.

B787 Operation Cycle

Boeing South Carolina is the only site that has the full production cycle –“freezer to flight”.

Freezer is the fabrication from raw composite material. (which is kept in a freezer)

From Fabrication, some assemblies go to Puget Sound and the others go to Final Assembly just next door.

Next is decorative paint.

After paint, airplanes go to the Flight Line for fuel, testing.

Final step is delivery.

The new 787-10 Dreamliner will be built exclusively in South Carolina. At 224 feet (68.27 meters) in length, the 787-10 will be the longest Dreamliner to date. Carrying 330 passengers in a two class configuration.

Aftbody and Midbody

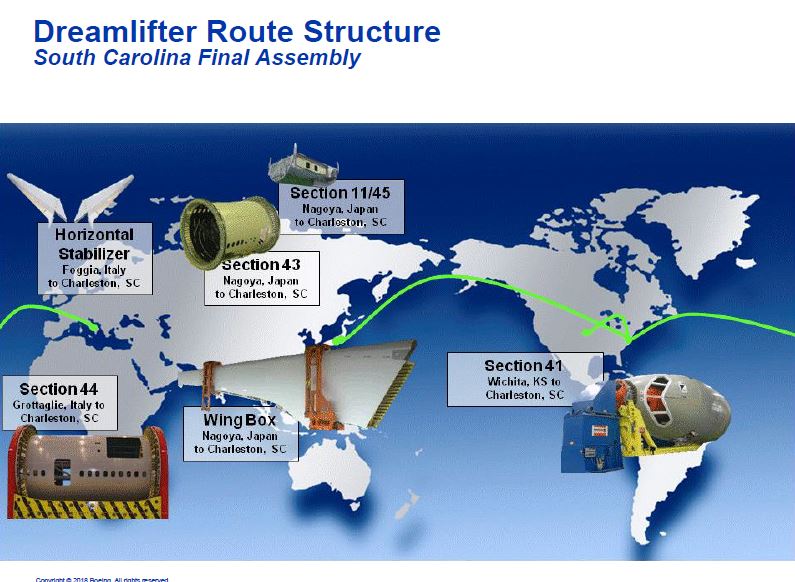

Every 787 aftbody and midbody is build in South Carolina, then some of them shipped to Everett, Washington by Dreamlifter and some of them were moved across by enormous cranes to the final assembly position at South Carolina.

The carbon-fiber tape used in the 787 is approx. 6.4mm wide and 0.2mm thick.

If all the carbon fiber used in a single 787 Dreamliner were streteched out in a line, it would reach from Charleston, SC to Los Angeles, CA - a distance of 2,200 miles.

The 787 is the first airliner with a fueslage composed of one-piece composite barrel sections rather than the thousands of aluminum sheets used in conventional airplane fuselages. This construction creates a lighter structure that uses 1.2 million fewer fasteners than the structure of a non-composite airplane.

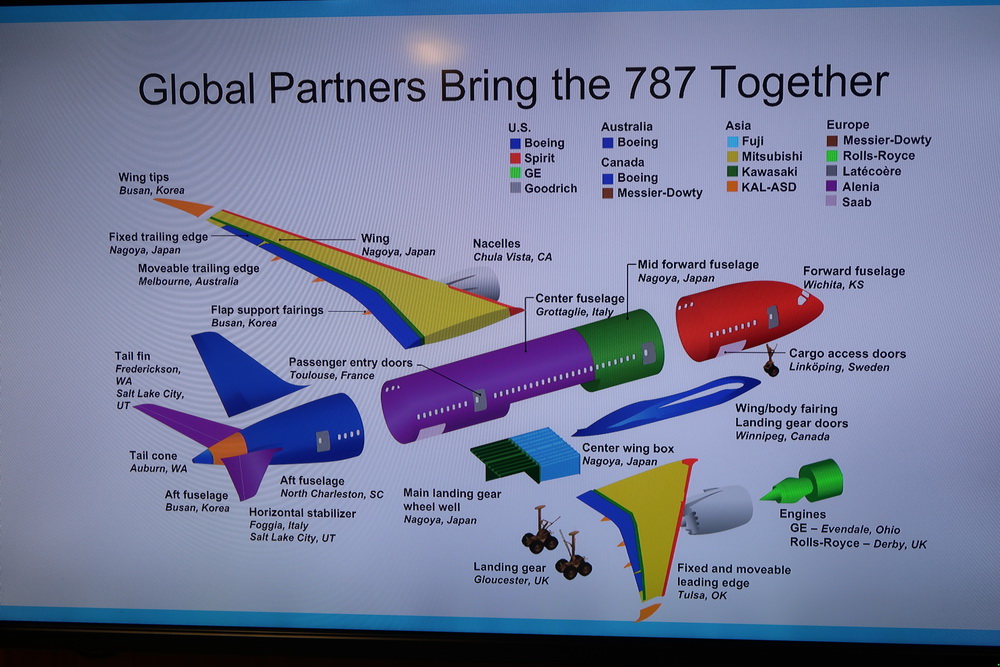

The below chart shows where the 787 components came from.

The below chart shows where the 787 components came from.

Interiors Responsibility Center

The interiors responsibility center team fabricates and assembles 787 Dreamliner interior components, including stowage bins, closets, partitions, ceiling panels, class dividers, overhead crew rests, video-control stations and flight attendant modules.

Singapore Airlines became the world's first Boeing 787-10 customer.