In October 2020, a Jetstar Airways Airbus A320 had performed an aborted take-off after the tip of a screwdriver left inside the engine caused unusual vibrations as soon as the pilots applied power for taking off. The aircraft was on its way to Cairns in Australia when the event occurred, forcing the pilots to abort the take-off.

The flight details

On October 23, 2020, Jetstar Airbus A320-200, registration VH-VFF was scheduled to operate a regular domestic flight from Brisbane International Airport (BNE) to Cairns Airport (CNS) in Queensland, Australia. During the takeoff roll, however, the aircraft started vibrating aggressively, followed by a gradually increasing popping noise as the thrust increased. Several passengers also claimed to see flames bursting out of the aircraft’s right-hand engine.

After the pilots struggled to control the aircraft, they aborted the take-off. As the aircraft diverged to the right of the runway’s centre line, the first officer’s application of the left rudder pedal did not help to bring the nose to the centre. The captain then applied reverse thrust, quickly decreasing the aircraft’s speed. The aircraft had reached a ground speed of 30 knots.

After the aborted take-off, all the 165 passengers and six crew members were evacuated, with no injuries reported.

The aircraft in question

The Airbus A320-200, with registration VH-VFF, was involved in the incident, as per the report issued by the ATSB. According to Planespotters.net, the aircraft was delivered to the airline in March 2012 and is currently 10 years old.

The aircraft is powered by two IAE V2527-A5 engines and is configured with 180 economy-class seats.

Screwdriver tip present for over 100 flights

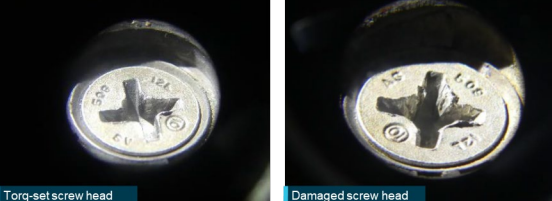

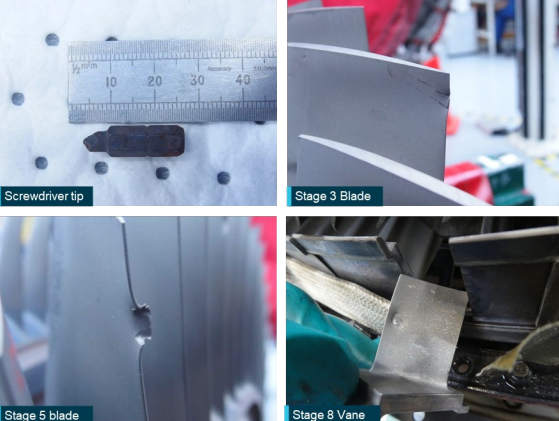

After the immediate incident, engineers inspected the plane to determine the cause of the incident. Small balls of metallic debris and a screwdriver tip were discovered between the combustion liner and engine case of the right engine. The screwdriver tip was found in the high-pressure compressor (HPC) of the right-hand IAE V2500 engine when it was disassembled. Further inspection found that six of the HPC stages had Foreign Object Debris (FOD) damage.

The Australian Transport Safety Bureau (ATSB) investigation concluded the screwdriver part had been there in the engine “for over 100 flights.” It had entered into the HPC when the engine was running. It was left during scheduled maintainence.

Damage to the aircraft parts

The tool bit caused damage to the high-pressure compressor, leaving dents and nicks in a number of rotor blades and stator vanes, as it was present there for over 100 flights, causing damage throughout the time. According to the final report, the screwdriver tip was eroded and burnt due to heat and mechanical damage.

The ATSB final report also concluded that damage caused by the screw tip inside the engine has made it difficult to divert the aircraft to the left of the runway’s centre line, despite the pilots’ attempt to bring the nose to the centre using the left rudder pedal.

“At least two of these defects initiated fatigue cracks that resulted in a blade failing during the occurrence take-off. The liberated blade caused greater damage to the HPC, and the engine surged,” explained the director of transport safety Stuart Macleod.

“Small and seemingly insignificant tool components can, and have, caused significant incidents or accidents,” Mr Macleod added.

What the airline representative said

Mike Chapman, Head of Safety at Jetstar, confirmed that the airline had issued a safety update to its engineering team on tooling checks and procedures, further describing the incident as “extremely rare.”

“When commencing take-off, our pilots detected a problem with the right engine. They aborted the take-off at a very low speed and returned to the gate.”

“We reported the event to the ATSB in accordance with regulations and assisted them in their investigation.

“We’ve issued a safety update to our engineering team on tooling checks and procedures to ensure this doesn’t happen again.”Head Safety of Jetstar, Mike Chapman

ADSB Full Investigation Report

Were you aware of this incident? Know of any similar events? Let us know in the comments.

Cover Photo: Wikimedia Commons